Tamra Transformer Conductor is produced in every conceivable ambience (Moisture controlled Dust free) to churn out flawless and better than best Copper & Aluminium conductor; with varieties of Insulation in comprehensive- spread from Kraft Paper to Glass Insulation and from single conductor to bunched to meet up exact requirement.

Tamra Oxygen Free Copper Wire Rod with less than 5ppm generates highest purity Copper, embracing Vertical Upward Continuous Cast process. Exclusive usage of LME Grade A copper cathode and rigid process control helps Tamra to deliver a product which is a class apart. Tamra has successfully nurtured a rare capability to produce Silver Bearing Copper.

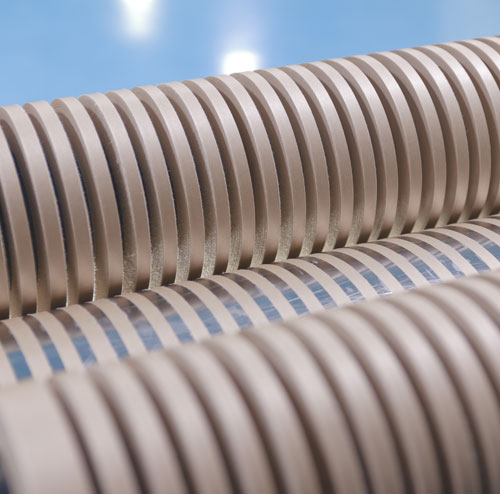

Rectangular: The continuous radial extrusion Conform process results into clean, deburred, smooth, round edged conductor’s soft conductor. Extrusions of both Copper & Aluminium are processed through superior Conform technologyto deliver best material.

Round: A scratch free annealed Copper / Aluminium wire are produced using the best European technology ensures Tamra to produce joint-less conductors of highest quality.

With a seamless bare conductor and with efficient insulating production line in a dust free moisture controlled atmosphere helps Tamra to guarantee a product ,which excels global standards.

The meticulous insulation line encompasses the gamut of transformer’s conductor like Kraft Paper, Crape Paper, Nomex, Mica, Polyster, Double glass and the variant of various insulation material required by the industry to meet varied applications.

Tamra is destined for ultimate success thru Quality Assurance right from Raw Materials to finished product passing through rigid quality checks of various electrical and mechanical parameters.

Tamra guarantees the super quality product through the stringent quality measures carried internally through its state-of-the-art lab, a few of which includes :

| Products | Types of Insulation | Range of Manufacture | Insulation Build Grade | Specification |

|---|---|---|---|---|

| Paper Covered/ Lapped Wire | Multi Lapped Manila/ Kraft Paper orCrepe Covering Butt Lap, Half lapwound and Multi layers |

6.4 to 0.50 mm | 0.05 to 0.125 mm Kraft Paper thickness or as required |

IS: 7404 Pt-1 BS: 4653: Pt-2 BS: 6811 Section 8,1 IEC: 317-27 |

| Paper Covered/ Lapped Strips | Multi Lapped Manila/ Kraft Paper orCrepe Covering Butt Lap, Half lapwound and Multi layers |

upto 100 Sq. mm | 0.05 to 0.125 mm Kraft Paper thickness or as required |

IS: 7404 Pt-1 BS: 4653: Pt-2 IEC: 317-27 |

| Nomex (Meta Armaide paper) Covered/Lapped Wires | Aromatic Polyamide Fiber Based Paper Covering Butt Lap, half Lap, Multi layer |

6.4 to 0.50 mm | 0.05 to 0.125 mm | IS: 11174 BS: 4653 Pt-2 IEC: 851 |

| Nomex (Meta Armaide paper) Covered/Lapped Wires | Aromatic Polyamide Fiber Based Paper Covering Butt Lap, half Lap, Multi layer |

upto 100 Sq. mm | 0.05 to 0.125 mm | IS: 11174 BS: 4653 Pt-2 IEC: 851 |

| Mica Composite covered/lapped strips |

Resin-Rich Mica Paper Glass Fabric or Polyester Film Composite, Single or Multi tape construction overlap or Butt wound |

upto 100 Sq. mm | Tape Thickness 0.10 to 0.33 | To Customers Specification |

| Kapton Covered Sintered Wire |

Polyamide film with Fluorinated Ethylene Propylene Bonding Covering Single or Double Tapes, over lap or Butt wound |

0.91 to 60 mm | Film Thickness 37 microns 62 microns 75 microns | To Customers Specifications IEC: 851 To Customers Specifications IS: 9148 |

| Kapton Covered Sintered Strip |

Polyamide film with Fluorinated Ethylene Propylene Bonding covering ¼ lap, 1/2 lap, 2/3 lap |

0Upto 60 Sq. mm | Film Thickness 37 microns 62 microns 75 microns | IEC: 851 S: 4685 BS: 1933 Pt-1 IEC: 317-31/32/33 IS: 10114/13730-0-4 |

| Glass fibre yarn Covered / lapped varnish/Resin Bonded Wire |

Insulation One/Two layer Glass Fiber Yarn Combination Enamelled |

0.30 to 6.4 mm | 1st layer 0.1 to 0.18 mm 2nd layer 0.19 to 0.43 mm + combinations of insulation |

IEC: 317-31/32/33 |

| Glass fibre yarn Covered / lapped varnish/Resin Bonded Wire |

Insulation One/Two layer Glass Fibre Yarn.Combination: Enamelled, Polyester Film, Nomex Paper |

Upto 60 Sq. mm | Layer 1, 0.10 to 0.18 mm Layer 2, 0.19 to 0.43 mm + combinations of insulation |

IEC: 317-31/32/33 |

| Insulation Type | Thermal Class | Standard | Applications |

|---|---|---|---|

| Kraft | 150°C | IEC 60317-27 | Oil-Filled Transformers |

| Nomex | 220°C | IEC 60317-52 & 53 | Dry-Type & Oil Filled Transformers |

| Polyester Film | 155°C | Acc. Customer Spec. | Special Transformers (Gas Transformers) |

| Kapton (Polymide Paper) | 240°C | IEC 60317-43 & 44 | Traction Motors |

| Mica | 155°C | Acc. Customer Spec. | High Voltage Motors - Generators |