TAMRA is an innovator when it comes to PV ribbon products. We have been supplying the Solar Industry with our copper products, continually identifying emerging PV Ribbon technologies and engineering innovative solutions to increase the electrical output and performance of solar modules.

| Item | Specification |

|---|---|

| Thickness (mm): | 0,080 – 0,500 ± 0,007 |

| Width (mm): | 0,300 – 6,000 ± 0,08 |

| Coatings (hot dipped) | |

| Lead free (RoHS complied): | Sn100; SnAgCu 96,5/3,0/0,5 |

| Leaded: | SnPbAg 62/36/2; SnPb 63/37; SnPb 60/40 |

| Low temperature: | SnBiAg 60/38/2 |

| Coating composition and thickness: | 4 – 50 µm ± 3 µm each side |

| Cu-OF1 CW007A (Acc. EN13602) | CDA 102 – Electrical Conductivity 101% – 103% IACS Resistivity ≤ 1,72 x 10-8 Ωm |

| Available Yield Strengths Rp0.2 (N/mm2) | <140 |

| <90 | |

| <70 | |

| <50 | |

| Elongation at fracture | >25% |

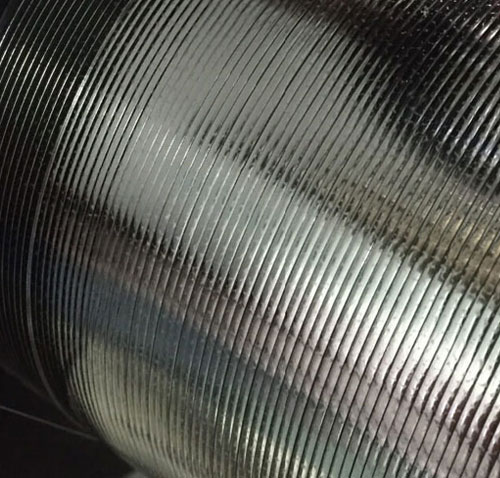

| Camber (mm/m) | <6 measured from the center of the spool |

| Spool type | d1 | d2 | d3 | L1 | L2 | Approximate winding volume in kg |

|---|---|---|---|---|---|---|

| SV 150 / 10-S | 152 | 100,5 | 16,1 | 121,5 | 101 | 5 |

| K160 | 160 | 100 | 22 | 160 | 128 | 8 |